"HammerheadFistpunch" (hammerheadfistpunch)

"HammerheadFistpunch" (hammerheadfistpunch)

02/27/2014 at 15:48 • Filed to: None

3

3

9

9

"HammerheadFistpunch" (hammerheadfistpunch)

"HammerheadFistpunch" (hammerheadfistpunch)

02/27/2014 at 15:48 • Filed to: None |  3 3

|  9 9 |

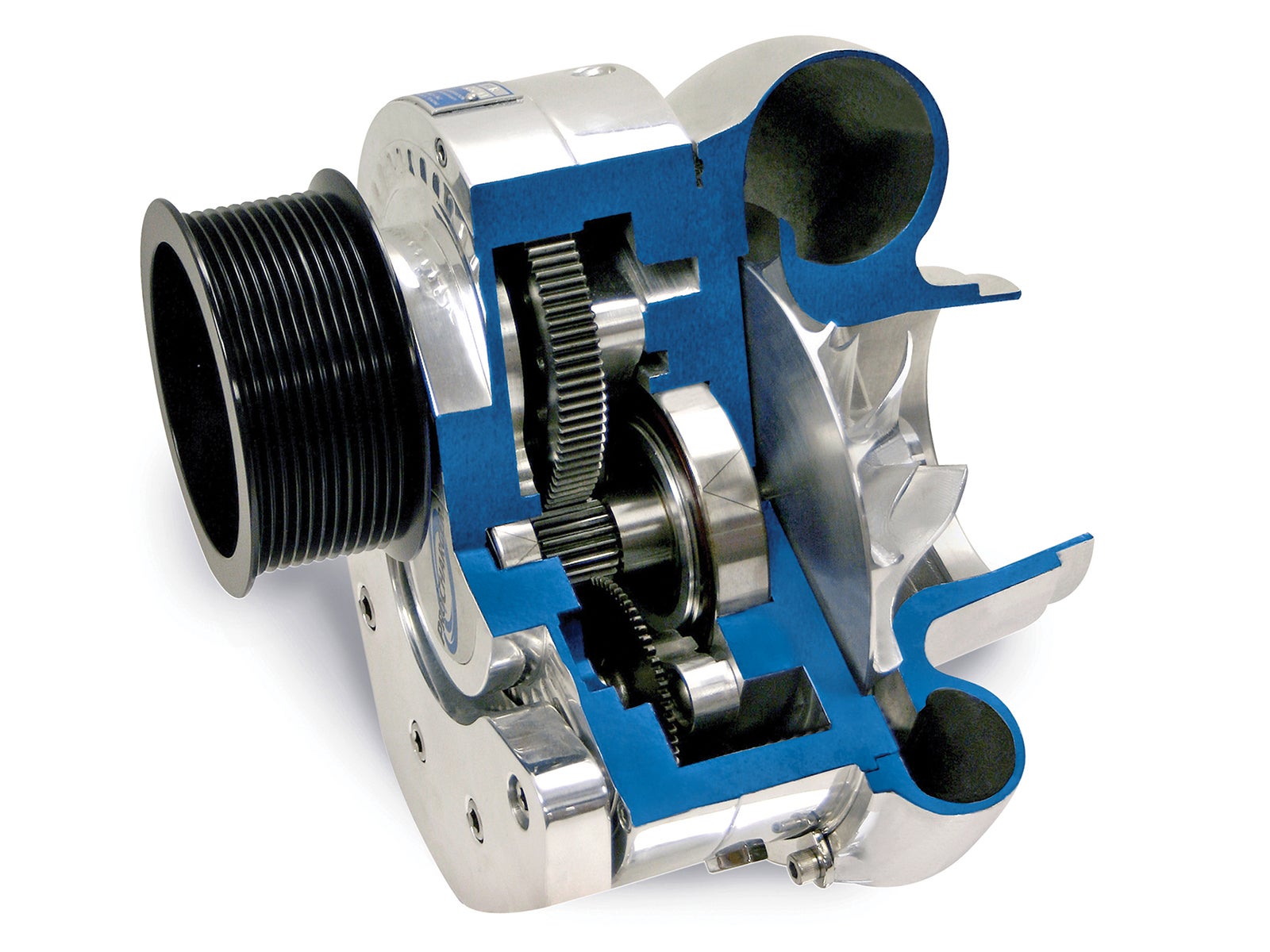

With the HKS supercharger !!!error: Indecipherable SUB-paragraph formatting!!! I was got to reading about the type of compressor on this. Its called a Rotrex and I will explain why its interesting in a minute, if its not immediately apparent.

!!! UNKNOWN CONTENT TYPE !!!

Because a centrifugal supercharger is just, more or less, a turbo without the exhaust driven turbine they require lots of speed to generate boost. In fact, the compressor needs to run at the same 200,000-250,000 rpm as a turbo does, but the problem is that, unlike a turbo that has a shaft linking the high speed compressor to a high speed turbine a supercharger is belt driven, which means your input speeds are in the thousands, not hundreds of thousands. To make this work you need to gear the compressor to increase the speed from engine speed to turbo speed.

Typically this is done with gears, but the Rotrex unit is interesting in that it doesn't have a single gear at all. If you look at the gif again, and in the source video here

you will notice what looks like a planetary gear reducer attached to the input. This is exactly what it is...with the exception that there are no gears. The benefit of going planetary is that you can reduce the size of the unit considerably over a geared unit. The interesting bit about the Rotrex is that they aren't using tried and proven gears, but instead use friction and smooth drums to act as the annular, sun and planet gears. I'm not 100% why, but I suspect its quieter, and you can get a little more gear reduction within the same size package. It uses a special petroleum based fluid to maintain viscosity and keep the heat down as well. Anyone with more science care to explain why rollers are better than gears? This concept has me intrigued.

RamblinRover Luxury-Yacht

> HammerheadFistpunch

RamblinRover Luxury-Yacht

> HammerheadFistpunch

02/27/2014 at 15:52 |

|

You get a lot of friction heating with gears too, and run into upper limits with how fast they can go. Deferring the friction heating to just the smooth surface slip amount probably makes sense. Ordinary gears if helical experience sliding slip between the teeth and irregular thrust forces, straight-cut gears experience pulsation - neither is a particularly good thing for insane RPM.

Casper

> HammerheadFistpunch

Casper

> HammerheadFistpunch

02/27/2014 at 15:54 |

|

I honestly don't know why they prefer the rollers to gears. I researched it quite a bit and what I gathered was more or less opinions ranging from higher efficiency from lower drag to less direct wear and tear all the way to ease of repair (replacement of fluid vs physical gears).

It's a really cool package, which is why I was interested in the HK kit. Before I saw that I was pretty much sold on the Innovate screw or the Full Blown Motorsport turbo kit if I needed more power.

HammerheadFistpunch

> RamblinRover Luxury-Yacht

HammerheadFistpunch

> RamblinRover Luxury-Yacht

02/27/2014 at 15:55 |

|

I remember with the procharger unit we had, lubrication was critical because of heat, I suspect that you are right since a lot of the engineering videos on this deal with heat soak and cooling.

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> HammerheadFistpunch

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> HammerheadFistpunch

02/27/2014 at 15:58 |

|

just applying logic:

1) no lash, built-in slipper-clutch functionality, alowing for smoother transitions of speed, perhaps integrating a "free-wheeling" mode to allow the compressor to maintain RPMs with inertia when input speed drops?

2) definitely quieter.

3) less chance for generation of particulate material in the lube bath (no gear corners to shear off)

4) Siginifficantly easier (and probably cheaper, even with the friction surface impregnation) to manufacture than precision gearsets.

5) Pure Awesome.

RamblinRover Luxury-Yacht

> HammerheadFistpunch

RamblinRover Luxury-Yacht

> HammerheadFistpunch

02/27/2014 at 15:58 |

|

There's also the fact that the comparative torque required is miniscule, so probably comparable to the shear force required by the liquid viscosity.

Tekamul

> HammerheadFistpunch

Tekamul

> HammerheadFistpunch

02/27/2014 at 16:01 |

|

From what I've read, it is supposed to generate less friction, further improving the higher efficiency of a centrifugal over a roots blower. But, I haven't seen hard science behind it, just sales-speak.

You can tell a Finn but you can't tell him much

> HammerheadFistpunch

You can tell a Finn but you can't tell him much

> HammerheadFistpunch

02/27/2014 at 16:41 |

|

According to Rotrex it is to reduce noise and increase reliability.

Key to the Rotrex supercharger's unique compactness, efficiency, low noise and reliability is its state of the art traction drive technology.

http://www.rotrex.com/Home/Technolog…

You can tell a Finn but you can't tell him much

> You can tell a Finn but you can't tell him much

You can tell a Finn but you can't tell him much

> You can tell a Finn but you can't tell him much

02/27/2014 at 16:44 |

|

In my quest for knowledge I stumbled across this bit of head explosion, but apparently Kinja. I do not understand harmonic drives . It can only be described as witchcraft.

Bruno Martini

> HammerheadFistpunch

Bruno Martini

> HammerheadFistpunch

02/27/2014 at 17:47 |

|

koinessegg.... (spelling?) used two rotrex units.

I wanted to get a set for my old 4.6L 3v.

Here are the pros.

Same install as a regular centrifugal but as big as an alternator.

More efficient than centrifugal supercharger.

Lower cost to obtain, immune to the cold unlike centrifugal units.

The cons are

- Very little support in the states for these. Almost no one uses them.

- Difficult to find a proper mounting option for these as they are rear mounted and not side mounted.